Tesla’s Optimus Robot Production Hindered by Rare Earth Shortages

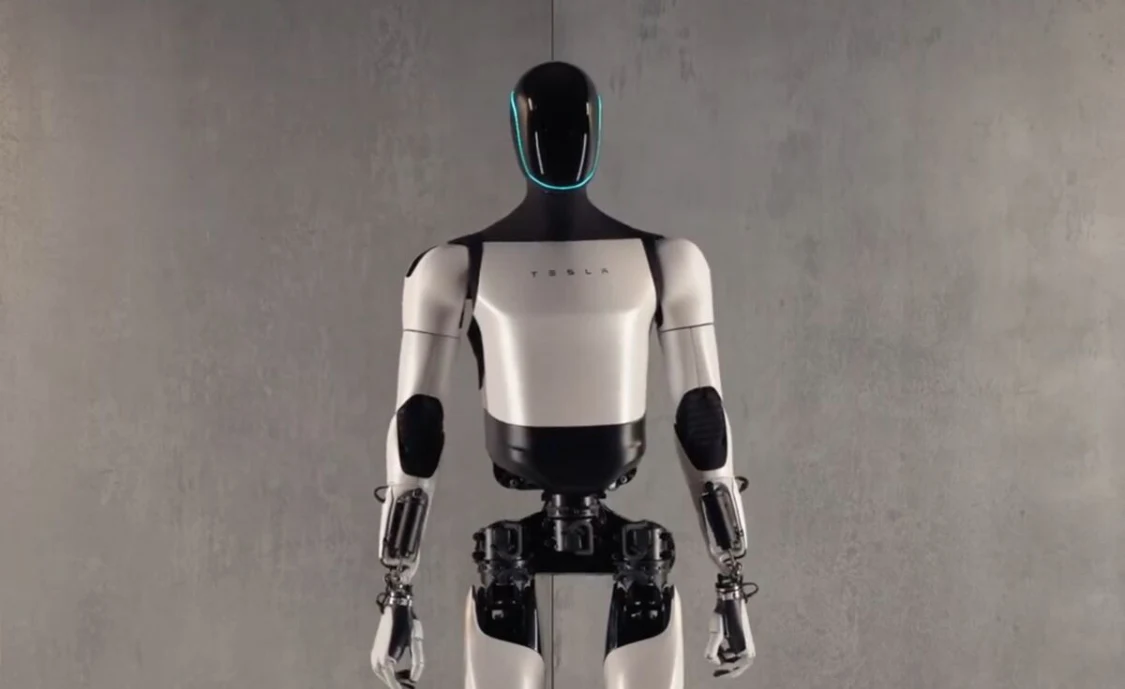

Tesla’s efforts to scale production of its humanoid robot, Optimus, have hit a significant roadblock due to ongoing global shortages of rare earth elements. These materials—particularly neodymium, dysprosium, and praseodymium—are essential for the powerful electric motors and actuators that bring the robot’s joints and limbs to life. Without a stable supply, production plans are slowing down, threatening Tesla’s timelines and innovation momentum.

Rare earth elements are used in nearly every high-performance electrical system, including the magnets inside Optimus’s joints that allow it to move smoothly and efficiently. Unfortunately, these materials are not only rare in nature but are also largely controlled by a handful of countries. China, which supplies the majority of the world’s rare earths, has tightened its export regulations in recent months amid rising geopolitical tensions. This has placed additional strain on supply chains and made it harder for Tesla and other manufacturers to access critical components.

Tesla CEO Elon Musk has previously emphasized the strategic importance of Optimus, calling it a key part of the company’s long-term vision for robotics and artificial intelligence. Optimus is designed to perform repetitive or dangerous tasks, with potential applications in manufacturing, logistics, and even home environments. However, the production of such an advanced robot requires not only sophisticated software but also an uninterrupted stream of specialized hardware—something rare earth shortages now threaten to disrupt.

The setback has prompted Tesla to explore alternative strategies, including potential investments in rare earth mining operations, recycling initiatives, and the development of motor technologies that require fewer rare earth materials. Still, such solutions take time to scale, and for now, the shortage remains a pressing obstacle.

Tesla’s current challenge is a reminder of the complex relationship between cutting-edge innovation and global resource dependency. As demand for intelligent machines grows, so too will the pressure on supply chains—making the race for rare earth independence more critical than ever. While Tesla remains committed to its Optimus vision, its success may hinge on how quickly it can adapt to this supply chain disruption.

0 Comments